Let’s cut to the chase. Here’s the problem I was observing. I had just performed injection port maintenance, replacing the septum, liner, and liner o-ring. I thermally conditioned the system before use. I injected a standard with two compounds, and my earlier eluting compound, endrin, appeared to be suffering from serious co-elutions. Glommed on to the earlier-eluting side were two significant peaks.

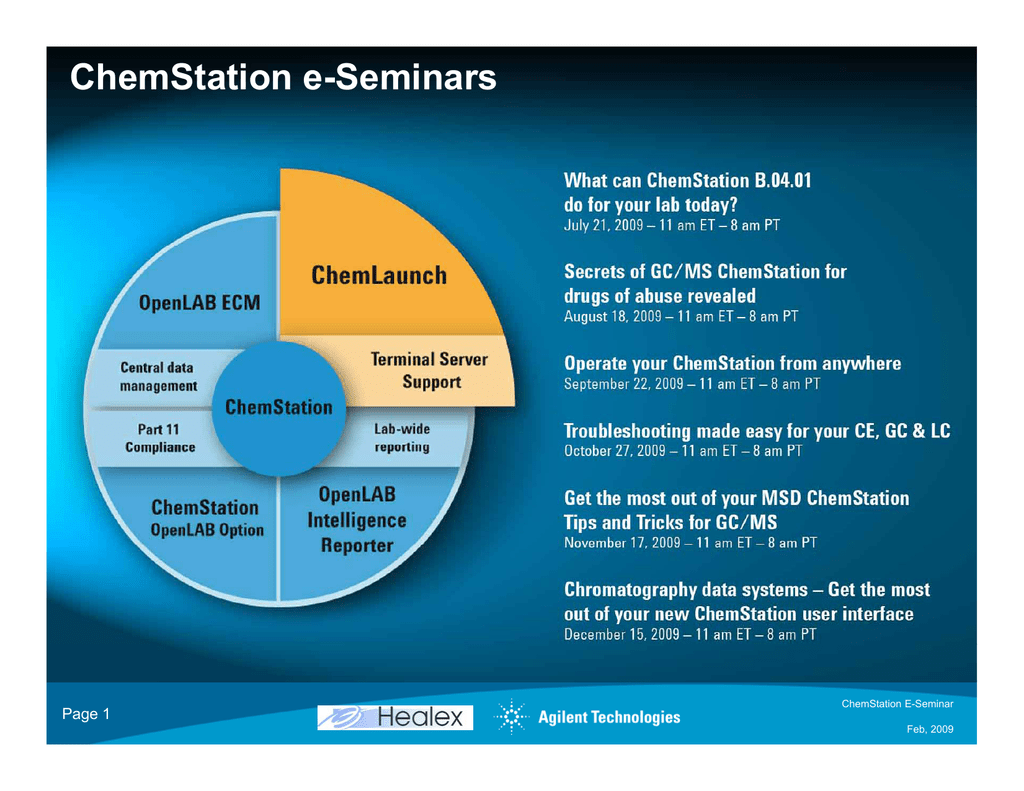

- Agilent Chemstation Troubleshooting

- Msd Chemstation Troubleshooting

- Agilent Chemstation Troubleshooting

Nuts.

- Troubleshooting TCP/IP LAN Communication Issues GC/LC/UV-Vis ChemStations on Windows® platforms. This document assumes your ChemStation was previously installed and working properly. Never use DHCP or allow IP addresses to be assigned automatically from other sources on your network.

- ChemStation Troubleshooting 123 7 Appendix 124 Privileges in OpenLab Control Panel 125 Sales and Support Assistance 132. ChemStation Edition Configuration 7 1Licensing License Management in the OpenLab Control Panel 8 Install your License 9 Overview on OpenLab license management with the OpenLab Control Panel.

- We got to the point chemstation was asking me to run%100 undiluted product to see if it would come off, which it didn’t, and probably damaged the lining on my hoses. A local chem supplier came in, I explained my problem, he gave me a gallon of caustic and a sequestering additive and it solved both problems.

Troubleshooting Communication Problems G1946C/D LC/MSD Networked Data System If you are seeing a 'communication failed' error message while starting up the on-line instrument session, the following steps should assist you in testing your system and determining the cause of the communication problem. Thread Problems with loading modified methods in Chemstation with 7890A GC. Problems with loading modified methods in Chemstation with 7890A GC Hello all. We have been having quite the hard time with out GCMS setup lately. We have a 7890A GC and 5975C MSD along with MSD Chemstation version E.02.00 with service pack 2 installed.

Now, instead of analyzing my sample, I’m troubleshooting. Why does it seem like I’m always troubleshooting? Surely it doesn’t have anything to do with me, right?*

So, I enter Troubleshooting Mode (yep, that’s actually a setting of mine…it’s just one ‘click’ away from Storm Out of Lab in Frustration mode, which is one ‘click’ away from Nap mode). I can be quite strategic when I’m in Troubleshooting Mode, and my favorite strategy is called “Defeat in Detail.” In this scenario I try to use my understanding of the situation to identify a number of likely causes of my problem, and then I begin to try to isolate and eliminate each cause using one of two possible ranking criteria; either “most probable to least probable,” or “easiest to hardest.”

Considering my problem involved the observation of multiple well-defined peaks that were consistent in retention time and peak shape, I surmised that my problem must be coming from before the column. I was clearly performing chromatography on the offending compounds, so they must have been introduced into the column. But where did they come from?

Well, my next question was whether or not they came from inside the instrument or from outside the instrument. Divide and conquer! Here’s where the “easiest to hardest” ranking comes into play, and where I finally get to the point of the post. I decided to perform a “no injection instrument blank.” This is a very valuable investigative tool, and it’s very easy to do with the Agilent GC Chemstation** software. Whether you’re starting your analysis from the “Sample Info” screen or the “Sequence Table” screen, if you simply leave the vial position field empty it tells the instrument to acquire data using the specified method but without making an injection. Now we should be able to determine if my mystery peaks were a product of the instrument or something I was introducing into the instrument.

And what did I observe? The culprits were still there! So, it was pretty clear at this point that I had a source of contamination inside my instrument. The next step I performed was to allow the instrument to sit for awhile with the oven at the initial oven temperature. When I ran the instrument again, sure enough I observed the same peaks only at a much greater intensity. This was another clear indication that whatever was causing my problems was a continuous source of the mystery peaks, and I was able to “trap” the compounds in the relatively cool oven.

My experience with modern septa and instruments with septum purge flows is that I don’t often observe these kinds of peaks unless I core the septa and a piece is sitting inside the liner. I had only punctured the septum a few times, so this seemed unlikely. The peaks also didn’t seem to follow the evenly spaced, late eluting, multiple-peak-pattern that often indicates septum bleed.

Agilent Chemstation Troubleshooting

This lead me to suspect my liner o-ring. I had installed an o-ring from another instrument manufacturer to evaluate it, and once I swapped out the o-ring and briefly thermally conditioned the system, the peak was nowhere to be seen!

Ah ha! Problem solved very deliberately and with very little down time. What might have happened if I didn’t perform the “no injection instrument blank” first and decided to explore my sample instead?

Why guess when you can divide and conquer, and this is a useful technique when you’re confronted with a contamination problem.

If you have any questions or comments, I’m always happy to hear from you!

* RIGHT?!

** I don’t think this works with Agilent MSD Chemstation or other instrument software platforms, but there are still ways to get it done. Write a comment if you have any questions.

Hi all--Msd Chemstation Troubleshooting

I am posting this on the chance that someone else may have experienced

this problem. We have the following system:

Agilent 5973N Mass Spectrometer (networked model)

Agilent 6890N Gas Chromatograph

Tekmar Solatek 72 Autosampler

Tekmar Velocity Purge and Trap Concentrator

Chemstation version D03

PC: Dell, running Windows XP Professional, with SP3. The PC also is on

Active Directory, and has a 'STIG' (security template) applied.

We are experiencing very intermittent failures on this system (every few

sequences) where the Chemstation instrument control throws and error,

and just shuts down. This has been going on since March.

The error is: msinsctl.exe

The instruction at 0x01180c2a referenced memory at 0x00000004.

The memory could not be 'read'. Click on OK to terminate the program.

We have done a lot of troubleshooting, mostly at the PC end, too many

things to list here. We are about to mount an all-out effort to fix the

problem. We are having problems diagnosing it, because it is so

intermittent.

Any help would be appreciated.

Agilent Chemstation Troubleshooting

Jim